Partnership with Volkswagen critical for EV localisation: M&M

Mahindra & Mahindra believes its partnership with Volkswagen will be the centrepiece of its localisation strategy for battery cells as demand for batteries that power EVs could rise as high as 60 GWh

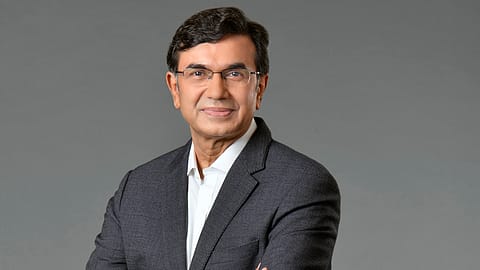

Homegrown carmaker Mahindra & Mahindra (M&M) sees its partnership with German carmaker Volkswagen as crucial in its plans to locally produce battery cells in the imminent future, Rajesh Jejurikar, executive director – auto and farm sectors, M&M, tells Fortune India in an interview. “We are looking at the localisation of battery cells, and that is where our partner Volkswagen comes into play, which is connected all the way down to the mines. That is the strength that they are building. The value leveraging with the partner who is investing $40 billion in the electric journey is this, and that is why we believe that partnership is the way to go,” he explains.

Currently, M&M plans to import the battery cells supplied by Volkswagen and do the assembly of the battery packs locally. “While we are also investing in technology, we are also investing in capacity. We are creating a separate capacity for our electric vehicles to achieve the volumes that we want to—which is 200,000 electric vehicles by 2027. This hopefully should be 30% of our total SUV volumes in 2027,” Jejurikar adds. In August, the Volkswagen Group and Mahindra signed the term sheet on the supply of Volkswagen’s proprietary Modular Electric Drive (MEB) electric components for Mahindra’s new electric SUVs. “Together, Volkswagen and Mahindra can contribute significantly to the electrification of India, a huge automotive market with ambitious climate protection commitments,” remarked Thomas Schmall, Volkswagen Group board of management member for technology and CEO, Volkswagen Group Components, at the signing of the term sheet.

Concurrently, M&M also applied for the Production-Linked Incentive (PLI)-scheme for advanced cell chemistries (ACC), which has an outlay of ₹18,100 crore. However, they were waitlisted in favour of other companies, namely Reliance New Energy, Ola Electric Mobility, Rajesh Exports, and Hyundai Global Motors Company. In a bizarre turn of events, Hyundai Motor India Limited (HMIL), issued a clarification that Hyundai Global is not affiliated with either HMIL or the South-Korea-based Hyundai Motor Company. Post the clarification, the government re-examined Hyundai’s bid, following which it withdrew its application. This has now put M&M in the fray of those who will be allotted the 20 GWh capacity. “We have not taken a decision on what will we do if we get the allocation,” Jejurikar says. However, he claims that Mahindra could be allocated a capacity of 5 GWh, which according to him, is “too less”.

China currently is the market leader in lithium-ion battery production with a 56% market share, whereas India has a high dependency on imports. Either Li-ion cells are imported from China or Taiwan to be assembled into batteries in India, or pre-assembled battery packs are imported. “One of the key challenges that India faces to realise its goal of establishing a local, robust manufacturing ecosystem is to overcome technological complexity. Battery cell manufacturing is a highly technologically complex process. Therefore, technology agreements with leading players are an option to mitigate risk,” says Rohan Kanwar Gupta, sector head, ICRA.

China also rules the roost in the processing of rare earth metals—with 58% of the world’s lithium processed in China, along with 35% of the world’s cobalt, and 40% of the world’s copper used in the manufacturing of battery cells, according to data compiled by ICRA. Cumulatively, 87% of the rare earth metals that are processed for this use are processed in China. ICRA also estimates that the capex requirement per GWh for a decent-sized facility could be around ₹400-500 crore. The demand for batteries, which power electric vehicles, is expected to be as much as 60 GWh by 2030 and could attract investments to the tune of ₹70,000 crore.

On asked why M&M pivoted towards electric over other decarbonising technologies, Jejurikar says that the move is done aligning with the government’s endorsement of electric vehicles. “At a national level, we need to understand why the government is keen on the EV journey. Along with the climate angle, there is also the issue of energy security and the economic issue of foreign exchange outflows. As a nation, we must achieve a better outflow of our foreign exchange reserves and greater energy security. Hybrid is not going to help us achieve that,” he says, adding that hybrid, at best, is a transition strategy. Going along the electric route for M&M will help align itself with the strategies of the government. “For us, it is the right thing to do,” he avers.