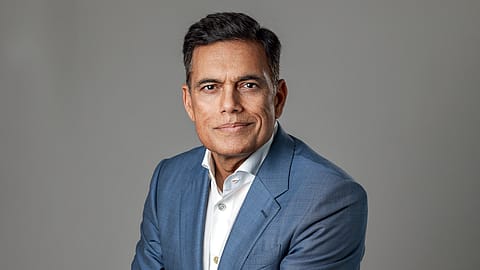

JSW’s Contrarian Bet Maker

Sajjan Jindal took his company places by acquiring struggling companies during market downturns and focusing on costs and exports.

This story belongs to the Fortune India Magazine October 2022 issue.

LAST SIX YEARS were not the most favourable for the Indian steel industry, but Sajjan Jindal, chairman of JSW Steel, made them count. He opted for big-ticket acquisitions when large steel companies were filing for bankruptcy. Despite the looming threat of dumping by Chinese steel companies, he invested in greenfield capacity — JSW Steel’s capacity doubled to 27 million tonnes (MT) in six years in spite of threats like Covid-19 and rising raw material costs.

Jindal is convinced that the steel industry will benefit from rising global spending on infrastructure and transition to green energy. He thinks Indian economy is the bright spot when recession fears are gripping U.S., Europe and Japan. “The idea is to keep our market share up in all core sectors where we are present,” he tells Fortune India. Steel consumption grew to 106 MT in FY22 from the pre-pandemic level of 100 MT.

The conviction has paid off. JSW Steel’s consolidated net profit rose 166% to ₹20,938 crore in FY22, while operational revenue rose 83% to ₹1,46,371 crore. Operating EBITDA rose 94% to ₹39,007 crore. EBITDA per tonne increased 61% to ₹21,454. Around 60% sales came from high-margin value-added and special steel. Capacity utilisation was 89%. U.S. operations turned profitable after years of losses. The company plans to sell some U.S. assets, including plate and pipe mill and its coal mining operation.

However, commodity inflation impacted costs. “While steel prices rose, we focused on cost efficiency,” says Jindal. He also ensured sufficient cash flow from exports, including to China, to meet fixed costs during the lockdown.

JSW Steel under Jindal made contrarian bets over the past three decades. In the 1990s, when Jindal was building a steel plant at Vijaynagar, the industry was in crisis due to high debt burden and poor demand. Most steelmakers, including Jindal’s company, defaulted on loans. It took the company five years to come out of corporate debt restructuring. The second time when the steel sector crashed, post the global financial downturn in 2008, JSW Steel was financially sound enough to play the predator and acquired sick assets like Ispat Industries and Welspun Maxsteel. It repeated this when Essar Steel, Bhushan Steel and Bhushan Power and Steel (BPSL), among others, filed for bankruptcy in 2007. JSW acquired BPSL for ₹19,350 crore, along with Aion Investment, and took over Monnet Ispat and Energy for ₹2,875 crore, renaming the company JSW Ispat Special Products. It recently announced a merger with JSW Steel.

JSW Steel plans to increase domestic crude steel capacity from 27 MT (which includes Bhushan Power and Monnet Ispat) to 37 MT by 2024/25. India, a cost-competitive maker of steel, has an opportunity to take on a larger role in global trade, says Jindal.

Last year, the company commissioned a new five MT capacity at Dolvi plant, which has India’s largest blast furnace and a steel melt shop. The expansion of Vijayanagar plant from 12 MT to 19.5 MT is also under way.

More Stories from this Issue

Ongoing expansions are oriented towards using more renewable power. Jindal has earmarked ₹10,000 crore for reducing carbon emissions by increasing use of renewable energy, improving raw material quality and deploying best technologies. “We have signed contracts for one GW of renewable energy, of which 225 MW became operational in April 2022,” he adds.

JSW Steel has implemented Industry 4.0 in the manufacturing process to improve operational efficiency. In September 2021, it became the first major steel company globally to raise $1 billion through a U.S. dollar-denominated Sustainability Linked Bond.