Good times ahead for technical textiles

While this category is still at a nascent stage in India, global demand is expected to grow to $220 billion by 2025, says a report.

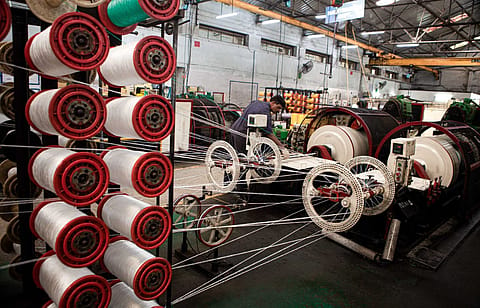

What is common to diapers, tents, fishing nets, helmets, jute sacks, bullet-proof jackets, stuffed toys, seat belts, and shoelaces? Technical textiles. What are they? Technical textiles are engineered products with a definite functionality. It is manufactured using both natural and man-made fibres—which have properties such as improved thermal resistance, higher tenacity, and excellent insulation. Such products find their use across sectors such as agriculture, healthcare, defence, construction, aerospace, automobile, and sports.

More importantly, this sunrise sector means big business. According to a recent Invest India report, the global demand for technical textiles is expected to grow to $220 billion by 2025 from $165 billion in 2018, at a CAGR of 4%. The report, titled “Technical Textiles: The Future of Textiles”, goes on to say that the Asia-Pacific has captured 40% of the global market, with North America accounting for 25%, and Europe at 22%.

According to the report, the region has seen such growth because of “rapid urbanisation and technological advancements in medical, automobile, and construction industries”, aided by “easy production, low-cost labour, and conducive government policy support”. In India, the market is estimated at $19 billion, growing at a CAGR of 12% over the past five years. “It contributes to about 0.7% to India’s GDP and accounts for approximately 13% of India’s total textile and apparel market,” the report says.

What has worked to India’s advantage? “Availability of raw materials such as cotton, wood, jute and silk along with a strong value chain, low cost labour, power and changing consumer trends are some of the contributing factors to India’s growth in this sector,” the report says. As a result, India’s technical textiles market shows a growth of 20% from $16.6 billion in 2017-18 to $28.7 billion by 2020-21, according to the Baseline Survey of the technical textile industry by the Ministry of Textiles. Let us come to exports. In 2018-19, India exported an estimated $1.9 billion of technical textiles, with exports growing at a CAGR of 4% over the past four years, the report says.

There’s room for more growth. Consumption of technical textiles in India is at only “5%-10% against “30%-70% in some of the advanced countries” according to the report. Therefore, a National Technical Textiles Mission has been set up “that aims at an average growth rate of 15%-20% to increase the domestic market size of technical textiles to $40 billion-$50 billion” by 2024, the report says. The mission plans to do so through market development, market promotion, international technical collaborations, investment promotions, and the Make in India initiative.

Besides the mission, the central government has taken various other initiatives such as allowing 100% FDI under the automatic route in this sector, and global biggies such as Du Pont, Procter & Gamble, Ahlstrom, Johnson & Johnson, and Kimberly-Clark, among others, have taken advantage of it. In 2019, the textiles ministry also “dedicated 207 HSN codes to technical textiles to help in monitoring the data of import and export, in providing financial support and other incentives to manufacturers”, according to the report. Besides this, the ministry also organises the flagship event, Technotex India, in association with FICCI. In terms of special schemes for this sector, most state governments have specific schemes. The Centre also set up integrated textile parks, eight centres of excellence, and the Amended Technology Upgradation Fund Scheme. Another boost comes in the form of the $1.4-trillion national infrastructure pipeline, announced in December. According to the report, the identified projects include energy, road, railway, urban development, irrigation, and health sectors, “where technical textiles can be used extensively”.

That is not all. The textiles ministry is in the process of creating “an ecosystem model that would allow creation of new mega textile parks exclusively for technical textiles and upgradation of existing 19 functional textile parks supported by the government”. But one also needs to develop a national textile policy, which meets the demands of today (the last one was released in 2000). Recently, the government suggested creating a special fund for R&D worth $13 million in technical textiles. “Along with these, more efforts will have to be made in the direction of fostering a well-developed R&D ecosystem,” the report says. To create a formal institutional structure, the report also proposes the formation of a National Centre of Research in Technical Textiles, tasked with monitoring long- and short-term research; “the centre should be encouraged to create international collaborations with the leading institutes around the world”, the report adds.

Recommended Stories

There is also a need to establish standards and focus on skilling. The report also proposes making the textiles ministry the administrative ministry for the Indian textile machinery industry—which is currently administered by is currently administered by the Department of Heavy Industries under the Ministry of Heavy Industries and Public Enterprises. “By making the Ministry of Textiles the administrative ministry for the Indian textile machinery industry, it is more likely that the industry will grow in sync with the overall textile value chain and also reap direct benefits of policies,” the report says.

While the technical textiles industry is at a nascent stage in India, it holds “vast potential for growth. With the government’s aim to create world class infrastructure in the country, in addition to the implementation of several policies and schemes to boost the textile sector,” the technical textiles segment is poised for growth, the report says. And useful physical properties such as durability, elasticity, and versatility make technical textiles even more useful “in times of changing climate, global warming, and complex industrial processes. Presence of large and global and domestic players has influenced the growth in technical textiles and has helped build sector prominence”.

The report concludes that the overall development of the infrastructure, coupled with the availability of skilled and low-cost labour, focus on research and development activities, and strong manufacturing capabilities “make India increasingly preferable as an attractive investment destination”.

And despite the economic slump and the overall demand for textiles going down because of the Covid-19 pandemic, the sector remains the second largest employer in India. “By transforming a Covid-19 crisis to an opportunity, India has proven its ability to innovate and rise to the challenge with limited resources and time. Therefore, it is even more essential for the government and industry to collaborate to boost technical textiles, a high-value segment of this sector,” the report notes.

(INR CR)